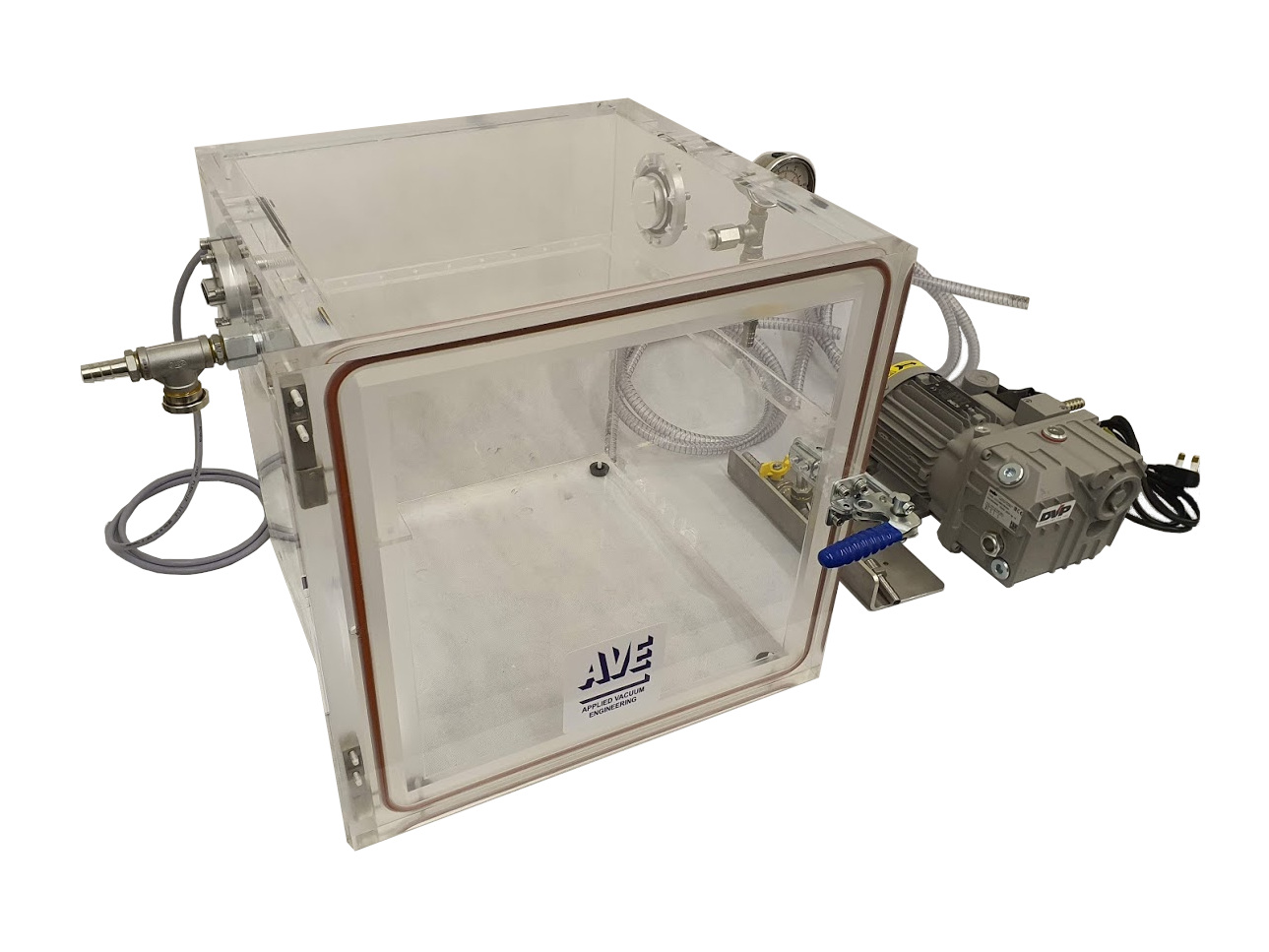

This innovative project saw a lot of ‘out of the box’ thinking and needed some careful designing and planning along the way. The finished item, however, looks stunning and is well up to the application it is intended for.

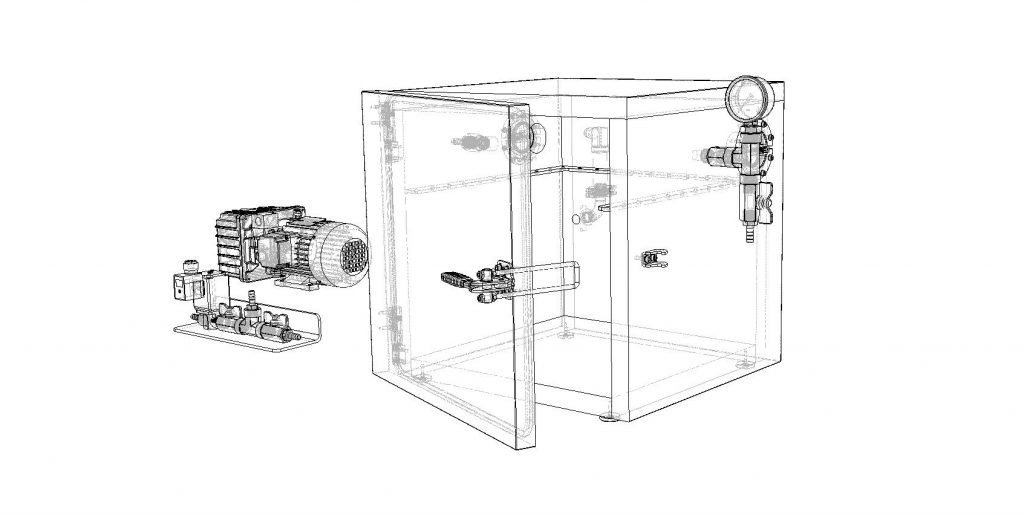

The customer came to us a few months ago with an application in mind and some design specifications for an acrylic vacuum chamber that would be important to them and their project. They wanted a vacuum chamber that could simulate atmospheric conditions at different altitudes, and at a different rate of ‘climbing’ to that altitude.

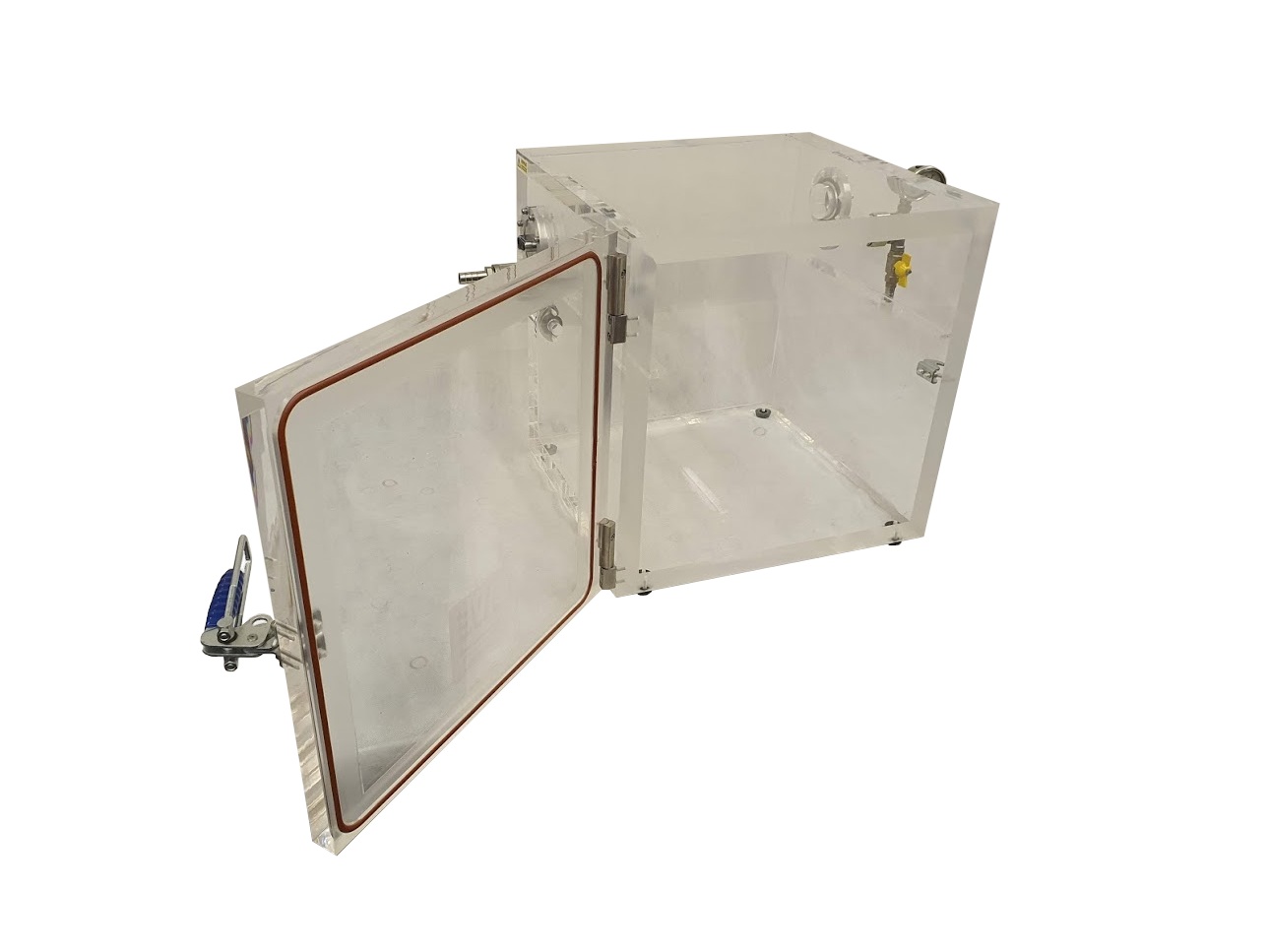

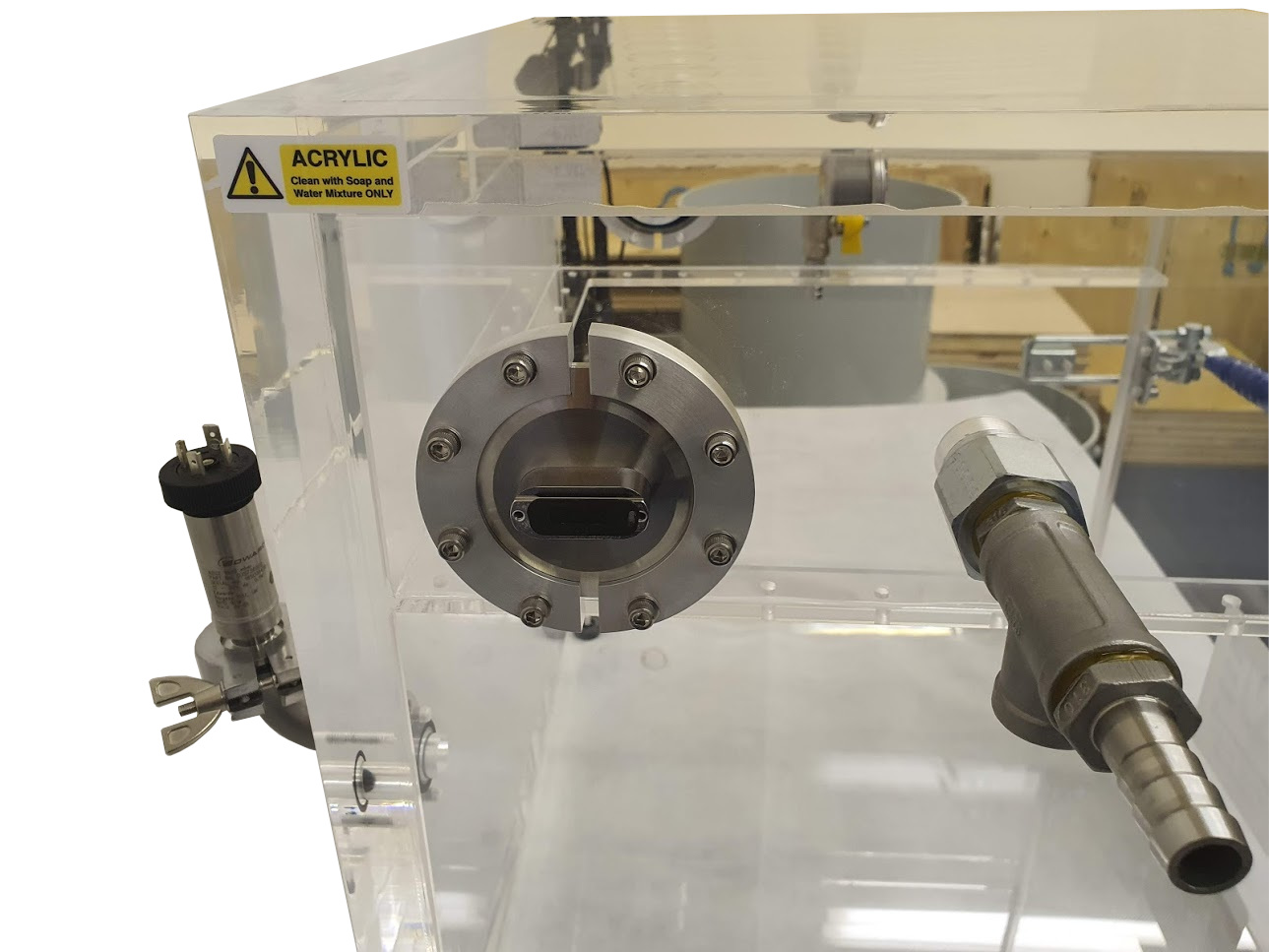

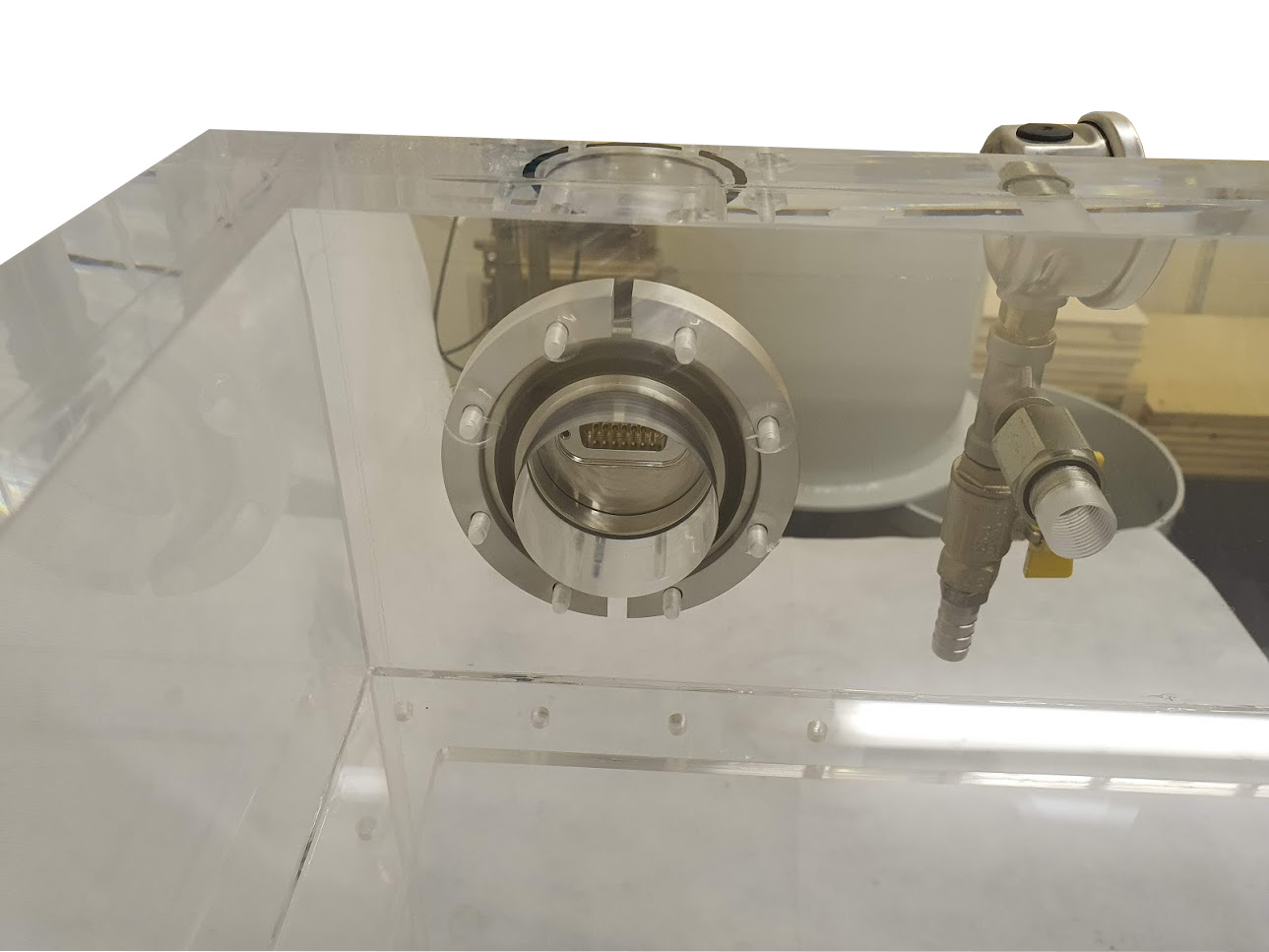

The vacuum chamber needed to allow for 360o vision so they could set observation cameras around. It needed electrical feedthroughs, to allow the implementation of sensors inside and to be able to read the data through a computer on the outside. They needed a ‘linear’ strain gauge to be able to electronically read the pressure inside the chamber, which was in turn attached to a proportional valve to control the flow rate and level of vacuum via a PLC. They needed to be able to gas flush the chamber after each use and lastly, the whole thing needed to fit inside a specifically sized faraday cage with the pumping manifold accessible from outside of the cage.

We set about sourcing all the electrical feedthroughs, strain gauges etc. and designing the chamber to accommodate them all. Inside the chamber the customer wanted a small shelf to attach the different sensors to, this presented its own little challenge.

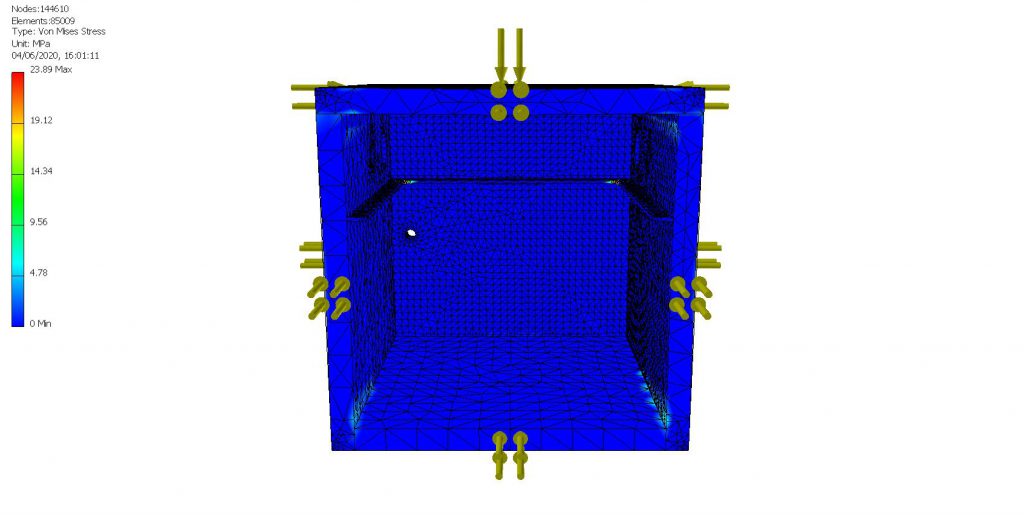

Normally in a vacuum chamber you don’t want anything against the walls because of the forces involved and deformation in the panels, the last thing we wanted was to crack the shelf on the first pump down, a nice radius on the corners helped reduce any stress singularities and a recess into the wall allowed for firm placement.

If you have ideas for your own project and would like to enquire with more information:

; ?>)